In the ever-evolving landscape of product design, from ideation to realization, 3D printing technology is revolutionizing contemporary design practices. 3D printing technology employs computer-aided design (CAD) and fabricates objects layer by layer. Commonly used in manufacturing, automotive industries, and industrial product design for creating tools, parts, and prototypes, this process, also known as additive manufacturing, layers materials like plastics, composites, or bio-materials to produce objects of varying shapes, sizes, rigidity, and color.

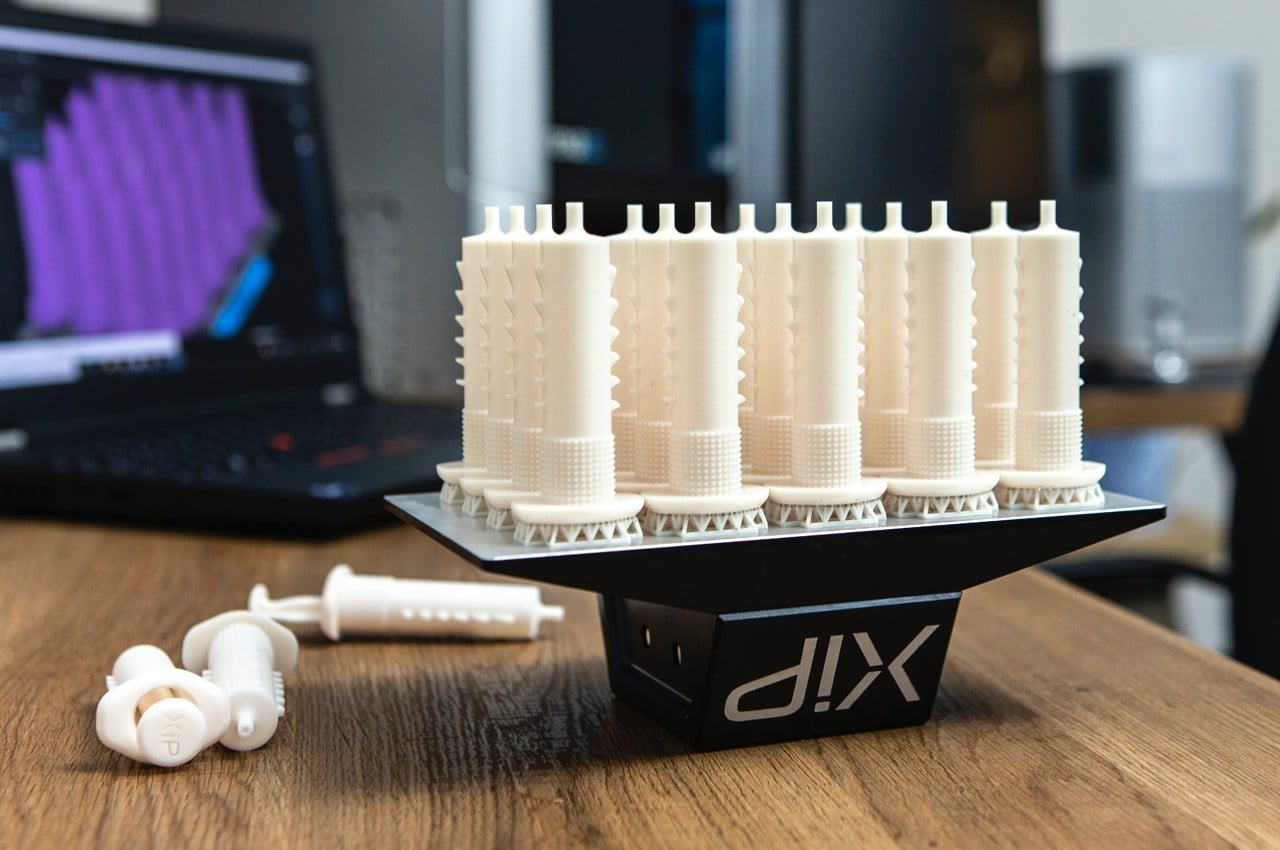

Designers: Nexa3D and Mocu Desig

The commonly selected 3D printing technologies include Fused Deposition Modeling (FDM), Stereolithography (SLA), Selective Laser Sintering (SLS), PolyJet, and Direct Metal Laser Sintering (DMLS). XiP is an advanced resin 3D printer by Nexa3D, offering professional-grade printing at speeds 6 times faster than SLA printers and over 10 times faster than filament 3D printers. With a 4.8L build volume and a 9.3″ 4K Monochrome LCD, it delivers crisp details. Its compact desktop design houses industrial LSPc technology, ensuring stability with a billet aluminum enclosure and precision ball screw Z-axis platform. The printer supports a wide range of resins, including proprietary formulations for diverse applications, all dispensed through smart recyclable cartridges.

What are the benefits of 3D Printing?

• Reduces Costs:

3D printing offers significant cost advantages over traditional manufacturing methods due to its automation, resulting in reduced labor expenses. Moreover, its minimal waste production leads to lower material costs.

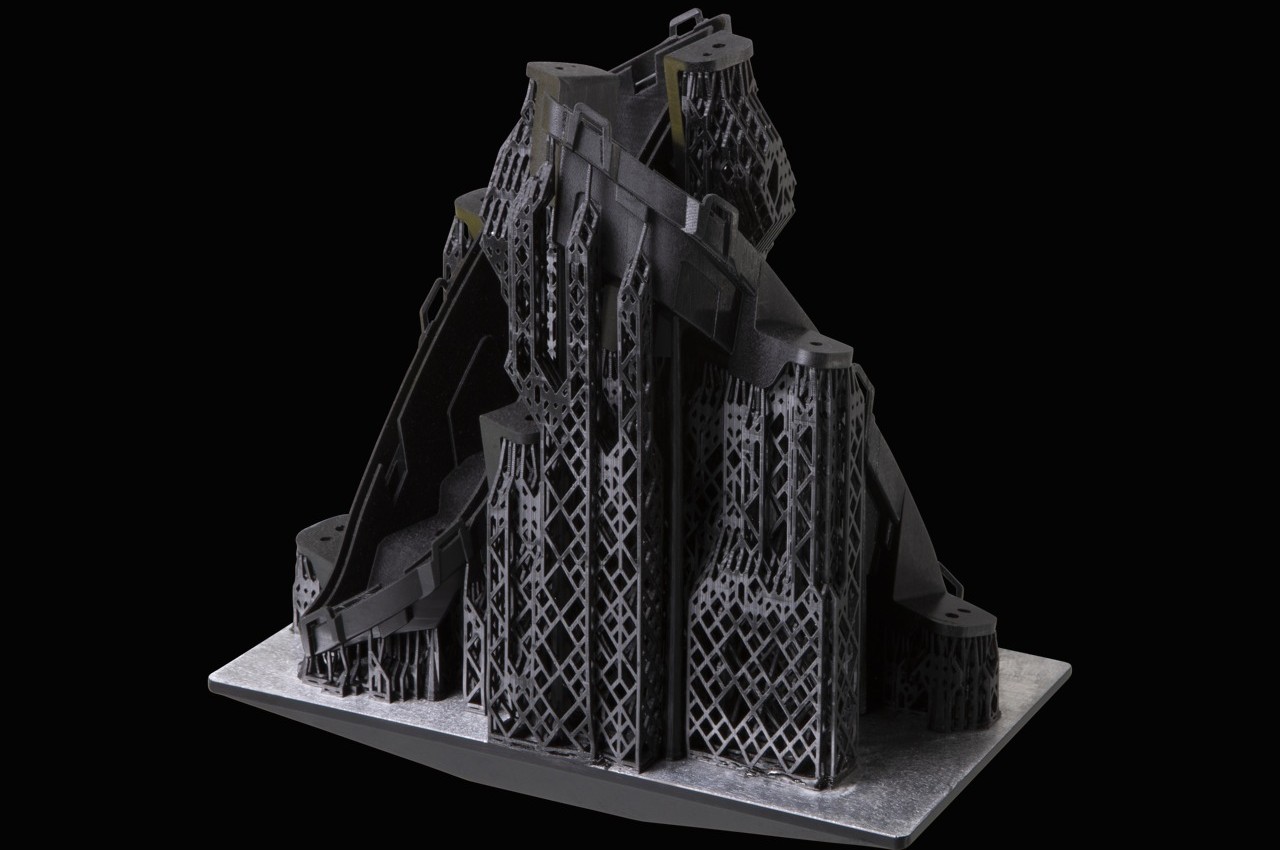

• Produces Complex Designs

3D printing exceeds the design constraints of traditional manufacturing, enabling the creation of intricate designs, including square or circular punctures or abstract designs with fewer restrictions.

• Promotes Internal Manufacturing

3D printers enable rapid prototyping, eliminating the need for outsourcing. This accelerates the design and production of new products, enhancing overall efficiency.

• Rapid Prototyping

3D printing enables the production of designs that were previously impossible with conventional manufacturing methods. By transforming digital files into physical parts within hours, this technology allows companies to adopt an on-demand manufacturing model for parts. 3D printing offers a comprehensive solution, facilitating prototyping, and short-run production, thereby transforming every aspect of businesses.

• Minimizes Waste

Traditional manufacturing generates substantial material waste due to inefficiencies while additive manufacturing minimizes waste by precisely utilizing materials, only using what’s necessary for each product or part. This is a great way to reduce material costs and improve environmental sustainability for companies.

• Manufactures Diverse Products

Industries across the board are leveraging 3D printing for a diverse range of products. From consumer goods like eyewear and furniture to industrial tools and automotive parts, technology is reshaping manufacturing. It’s also vital in healthcare for prosthetics and orthotics alongside architectural models. Additionally, the film industry benefits from 3D printing for creating intricate props.

Top 10 Examples of 3D Printing in Product Design

Here are Top Ten examples of how 3D printing is used in product design across various product types:

1. Handbags

Designers: Julia Koerner, Kais Al-Rawi and Emma Sanson

Acclaimed Australian designer Julia Koerner merges nature and computer algorithms with 3D printing and innovative resin-based techniques to create her award-winning handbag collection, resulting in visually lightweight yet rigid designs with a distinctive skeletal aesthetic. Inspired by the organic shapes of dried kelp found along the Pacific coastline, Koerner’s KELP MINI handbag seamlessly blends artistry with functionality. Each meticulously crafted handbag is created with sustainable plant-based materials and solar-powered manufacturing, offering clever design elements like hinged bases and snap closures, making them ideal for storing essentials with style and efficiency.

2. Tiles

Designer: bioMATTERS

MYCO-ALGA presents a groundbreaking interior tiling solution that transforms bathroom aesthetics. These 3D-printed tiles are crafted from repurposed natural waste and living organisms, featuring captivating designs inspired by organic forms. Sustainable at every stage, MYCO-ALGA tiles undergo a precise process encompassing digital design, 3D printing, organism cultivation, and bio-pigment enrichment. As a result, the outcome is eye-catching tiles with unique, non-repeating patterns resembling crawling organisms, that offer both lightweight durability and visual allure that effortlessly merge style with sustainability.

3. Air Purifiers

Designer: External Reference

Barcelona-based company introduces Pure Plants, 3D-printed sculptures doubling as air purifiers. Utilizing Pure.Tech technology efficiently absorbs and neutralizes indoor pollutants like carbon dioxide and nitrogen oxide. Mimicking plant structures with geometric patterns, these sculptures enhance decor while promoting healthier indoor air quality. Crafted from sustainable Pure.Tech biomaterial and PLA bioplastic derived from corn dextrose integrate aesthetics with eco-consciousness.

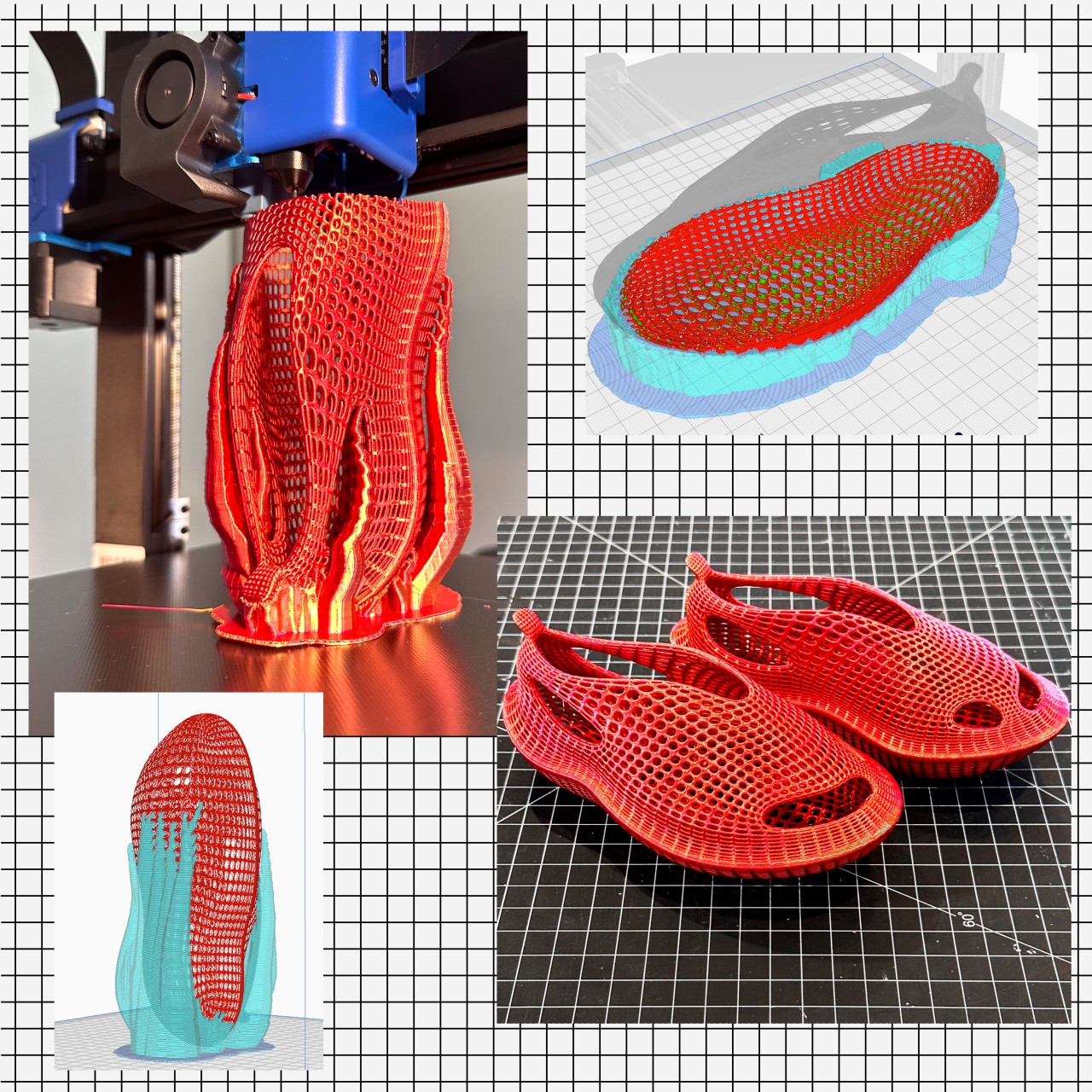

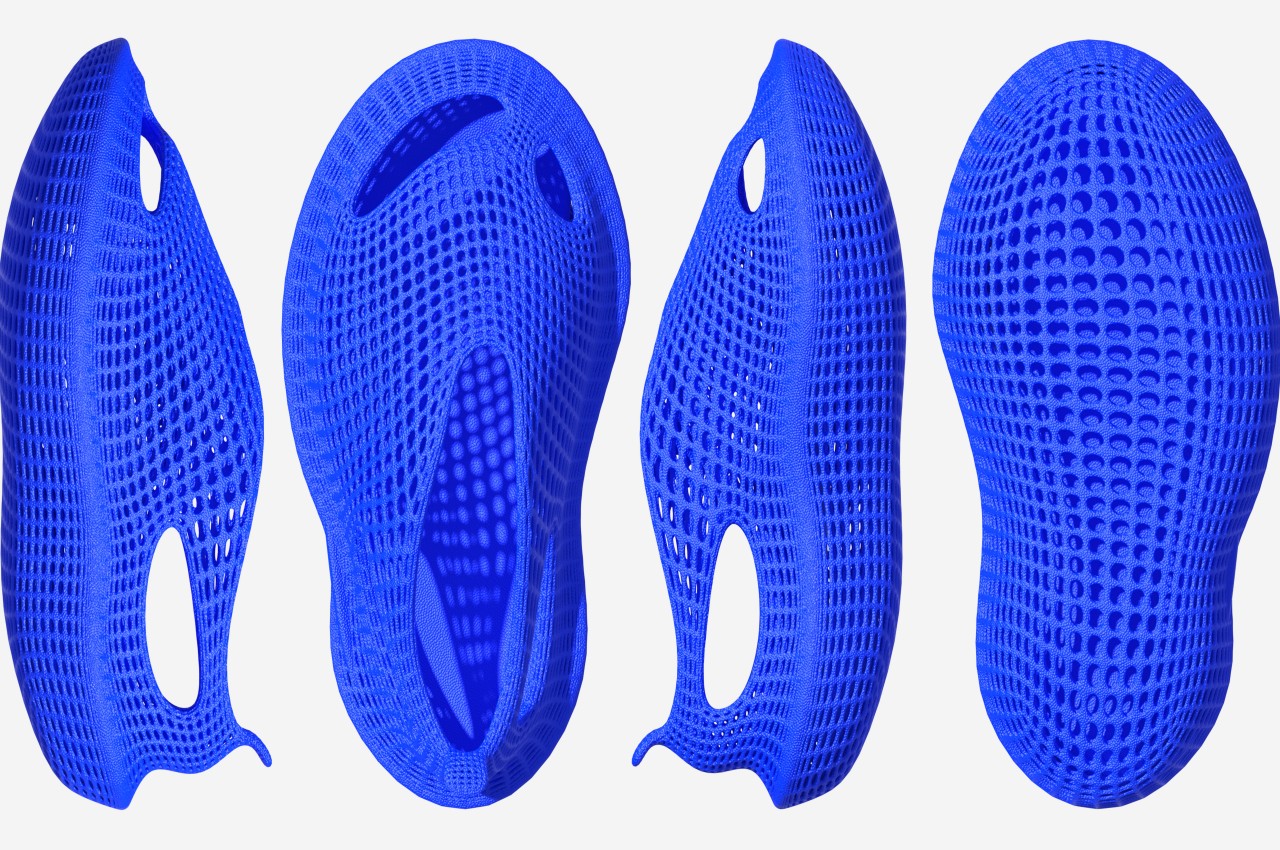

4. Footwear

Designer: Matthew Blunt

EXPLR 02 is a futuristic 3D-printed shoe blending wireframe-inspired aesthetics with organic elements. Crafted with advanced techniques, it epitomizes modern manufacturing’s versatility. While challenging footwear norms, questions linger about real-world durability. Yet, EXPLR 02 signifies a leap in innovative, personalized shoe designs, shaping the evolution of 3D-printed footwear.

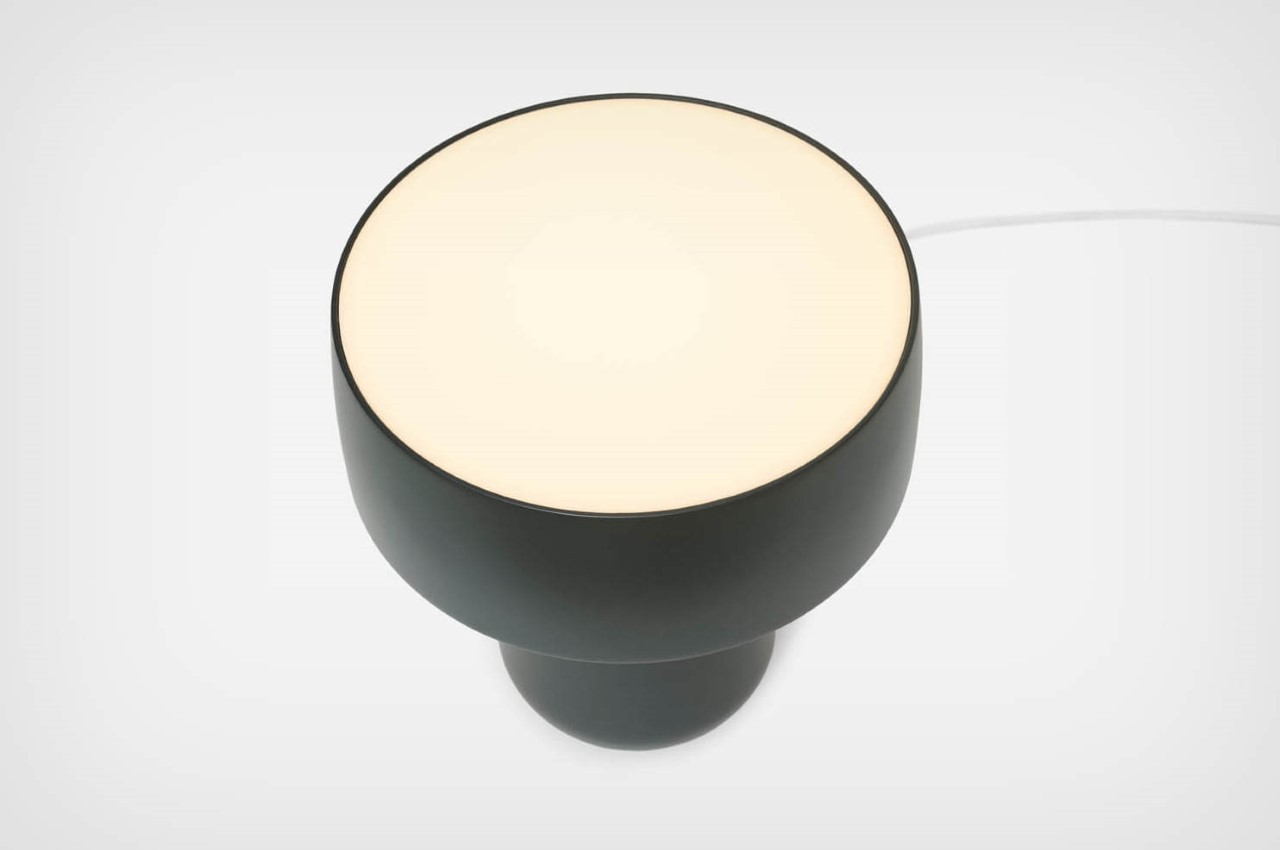

5. Table Lamp

Designer: Felix Pöttinger for Gantri

The 3D-printed Hula table lamp, envisioned by Felix Pöttinger, ingeniously merges direct and indirect lighting to efficiently illuminate spaces, tackling urban living challenges by minimizing glare. Its ring-shaped shade, reminiscent of a hula hoop, is available in Snow, Forest, and Blossom Pink, adding a distinct flair to any setting.

6. Living Soil Walls

Designer: Ji Ma, David Carr, Ehsan Baharlou, and Spencer Barnes

The University of Virginia research team has developed an innovative 3D printing method using soil infused with seeds to create plant-covered structures like walls and roofs. The team’s eco-friendly approach integrates greenery into architecture, providing natural insulation, flood prevention, and green spaces. By minimizing materials and utilizing locally sourced resources, their process reduces emissions and waste. With plans to expand their prototypes and improve their soil ink formula, the team aims to contribute to carbon-neutral construction.

7. 3D Printed Homes

Designer: Progreso x COBOD

Architecture is no exception in the age of ubiquitous 3D printing, with many firms favoring this method for building structures. Cement company Progreso recently collaborated with COBOD to construct Guatemala’s first 3D-printed building to withstand seismic activity. This compact home, completed in just over 24 hours, merges modern construction techniques with traditional craftsmanship, featuring organic-shaped walls and a traditional palm leaf roof. With a footprint of 527 square feet, the structure operates as a fully functional living space capable of withstanding extreme seismic events.

8. Chairs

Designer: Johannes Steinbauer Office For Design

Oeschler’s new manufacturing technique, demonstrated in Johannes Steinbauer’s Office for Design’s 3D-printed seats, eliminates traditional materials while maintaining comfort and functionality. 3D printing is reshaping furniture design and manufacturing, introducing innovation in sustainability and functionality. With a simple yet versatile design, these chairs offer easy assembly and recyclability, signaling a promising future for 3D-printed furniture in the industry.

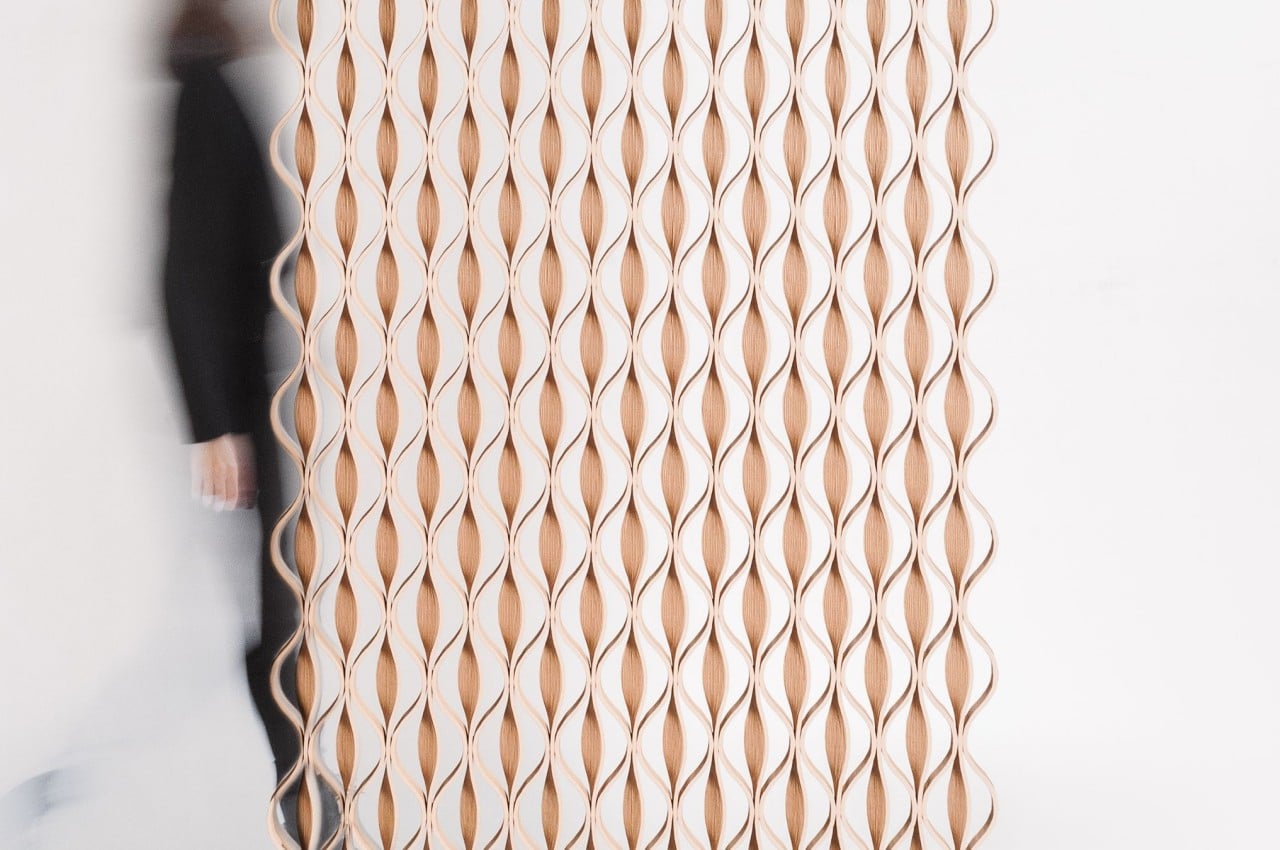

9. Recycled Wood

Designer: Aectual

Wood is a preferred choice for its eco-friendliness, yet shaping and recycling pose challenges. Enter 3D-printed wooden partition screens and window coverings, offering a breakthrough solution. While 3D printing democratizes design, it also increases material waste, prompting a search for sustainable options. Crafted from wood waste and fortified with natural elements, this innovative material resembles wood in appearance, texture, and scent. Moreover, its circular lifecycle allows for recycling into new forms, minimizing waste. Despite potential production cost concerns, its promise for intricate designs and sustainability makes it attractive for environmentally conscious designers.

10. Homeware

Crafted by Vienna-based designer Nicolas Gold, renowned for his expertise in “Tiny Furniture,” this collection employs 3D printing. The range comprises vases, bowls, planters, and lighting, all crafted from lightweight, recyclable bioplastic sourced from corn. This blend of architectural precision and modern technology results in sophisticated homeware where design, architecture, and 3D printing harmonize seamlessly. The Tiny Architecture collection showcases intricate patterns such as the asymmetrical Bloz and fabric-like Fald, crafted from partially recycled materials to enhance their individuality.

The post 3D Printing is Shaping Modern Product Design: Here’s How first appeared on Yanko Design.

0 Commentaires