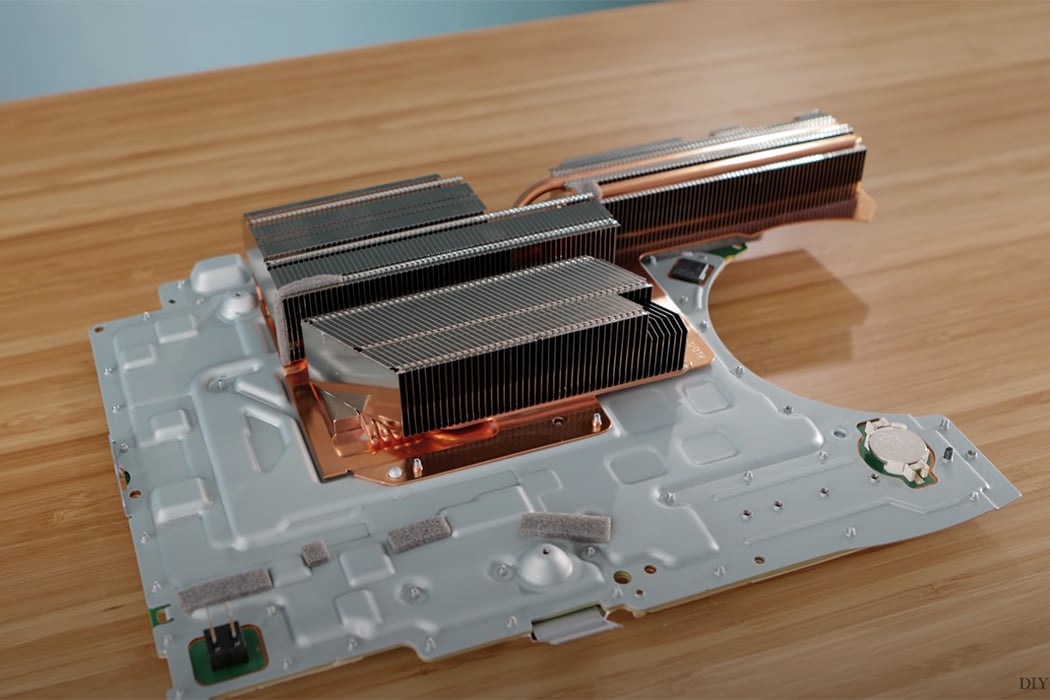

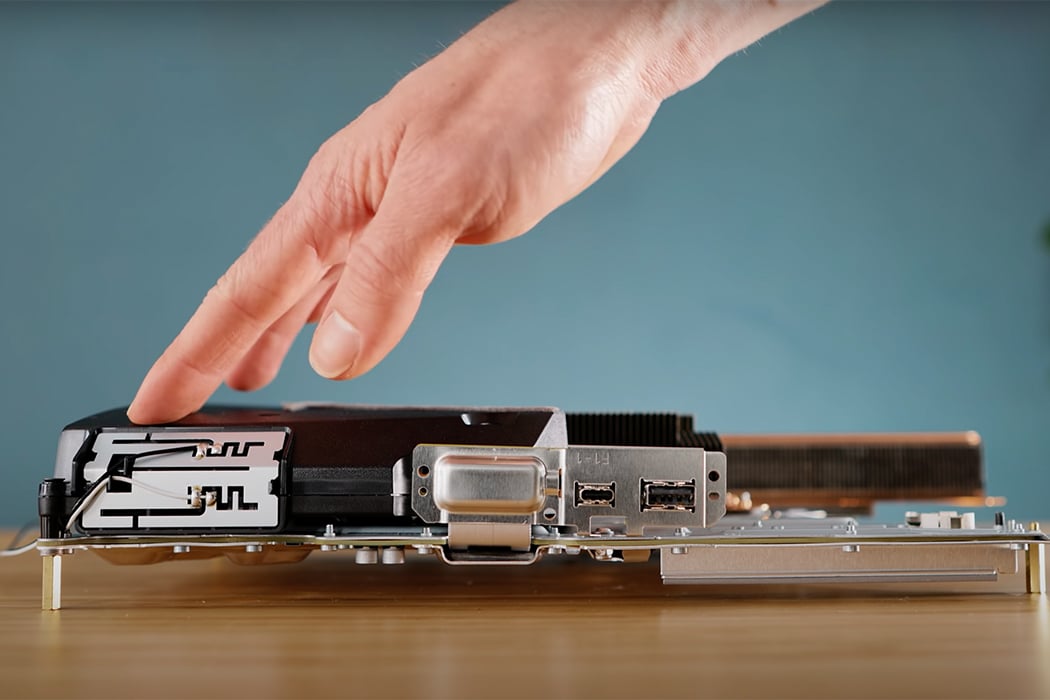

Matt, of DIY Perks is back again with another custom hack that you can build in the comfort of your own home. This time, the handyman YouTuber designs and constructs a wooden case for his new PS5. DIY Perks starts his process off by disassembling the casing of PS5 to keep only the core of the unit. Left with a compact and thin inner structure, the bulkiest aspect of the PS5’s internal workings is the cool and heat sink. Since the core of PS5 cannot remain leveled on a flat surface, DIY Perks evens out the structure with a few hexagonal PCB pillar supports. Then, using long screws, the PS5’s power supply latches and securely fastens on top of the leveled-out inner structure. DIY Perks then takes a sheet of carbon fiber, a tough layer of woven crisscrossing carbon fibers, to form the case’s base plate.

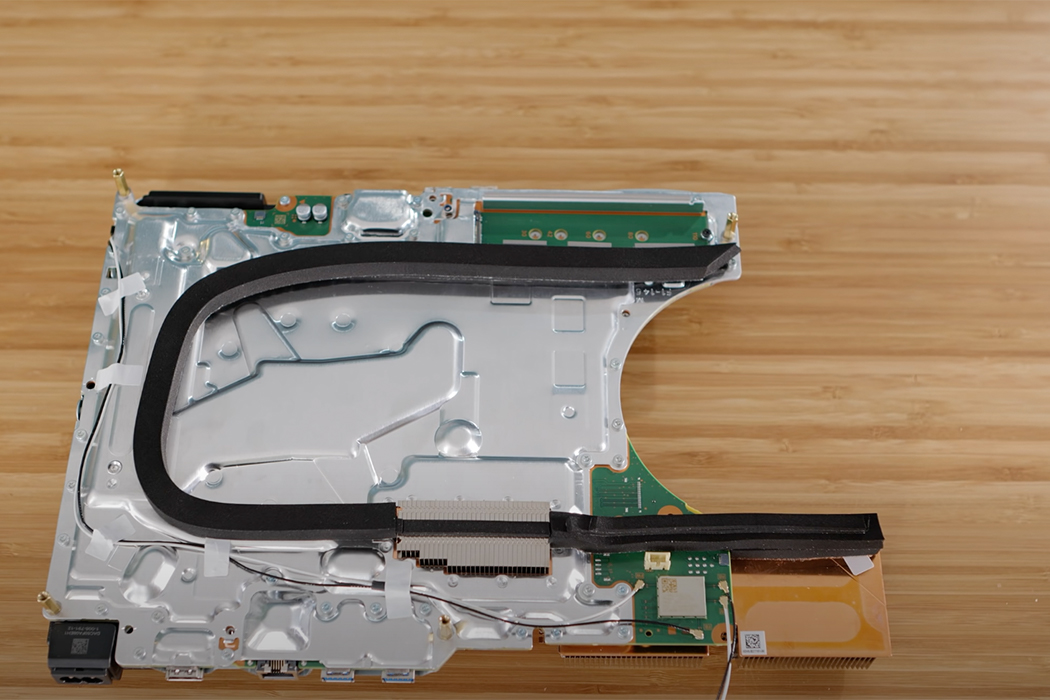

Carved into the base plate, DIY Perks creates holes where the rest of the PS5’s components fit. Next, DIY Perks mounts the system’s fan onto the carbon fiber baseplate, overlaying the fan with a grill to prevent anything from getting caught in the fan’s blades. Divided into two halves, the fan pulls air in through both sides, allowing airflow drawn from the heat sink to exit through the carved hole in the carbon fiber base plate. To direct the airflow from the heatsink to the fan, DIY Perks uses strips of foam, a cue taken from Sony.

With the inner system securely fastened to its new carbon fiber baseplate, DIY Perks begins work on the system’s American walnut wood case. Using a Japanese saw blade, DIY Perks carves angled edges on the walnut wood to create a cubic frame. Before situating and locking the PS5 into place within the wood frame, DIY Perks etches holes for the USB cables to reach their port located inside the wooden frame, on the PS5 system itself. Leaning on the holes he previously carved into the carbon fiber base plate to mount it onto the wooden frame, both pieces easily merge with one another.

With the rear side of the case still exposed, DIY Perks uses a CNC router to carve port slits that work as vents for the system to remain cool. Finally, DIY Perks looks to carbon fiber once more for the case’s lid, where he relies on CNC milling to carve a vent for the fan out of miniature hexagon shapes, marrying them to the walnut frame with matching hexagonal wooden inserts. The refined walnut look of the case is certainly a step away from the original metallic and custom brass casing for the PS5. Understated and sophisticated, the new case from DIY Perks doesn’t demand your attention like the original shiny metallic case, but the rustic elegance of the walnut wood blended with the durability of carbon fiber definitely keeps it.

Designer: DIY Perks

The combination of walnut hardwood framing and carbon fiber covering gives the custom PS5 case a retro feel.

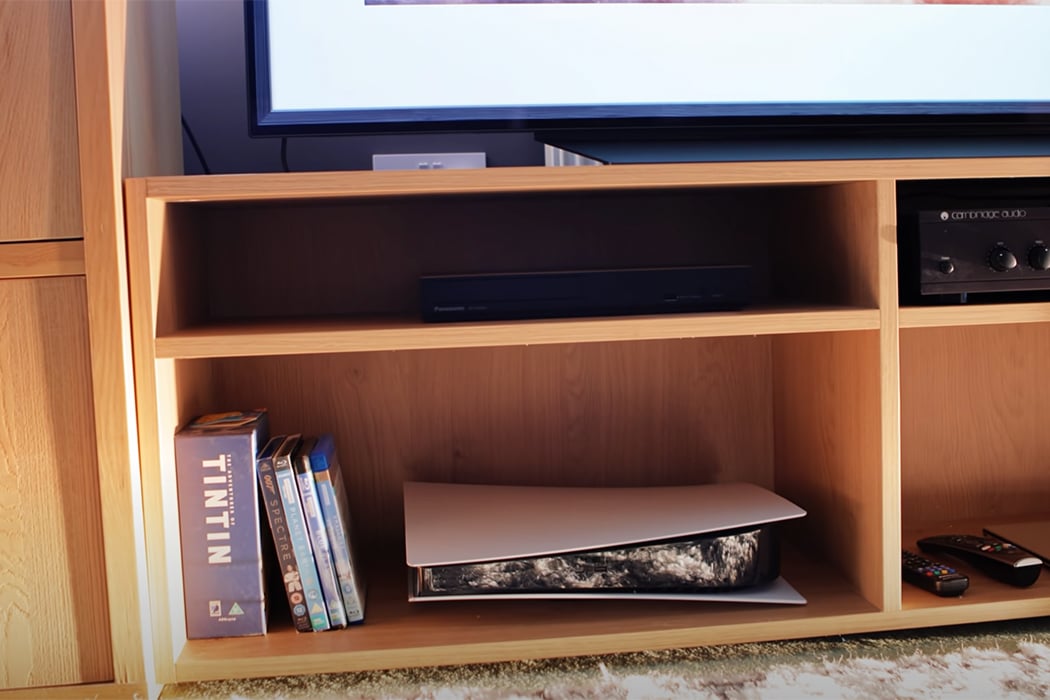

Without a flat surface, when the PS5 is laid horizontally, it doesn’t fit in entertainment consoles.

DIY Perks began by disassembling his PS5.

The cool and heat sink is the bulkiest part of the gaming system.

In order to level out the inner structure, DIY Perks inserted brass washers with varying heights on both ends of the system.

Matt took to a carbon fiber base layer to form the system’s bottom covering.

Matt inserted a grill for the fan’s opening to permit and promote airflow.

Additionally, he inserted a foam strip to direct the airflow.

Using a saw blade to cut the walnut framing’s sides, Matt created a wooden border for the PS5 case.

Hexagonal port holes help to keep the inner workings of the PS5 cooled down.

0 Commentaires