MIT scientist Yoel Fink has worked on developing smart fabrics for longer than a decade. In 2010, Fink and some of his colleagues produced fibers that could detect audio. A first for smart fabric developments, the fiber could be woven into a fabric, which transformed it into a needle-thin, working microphone. Today, the team of scientists continues work on spinning fibers into the smart fabric but moves past analog capabilities towards a digital future, weaving fibers that carry continuous electrical signals into a piece of wearable smart fabric.

Published in a Nature Communications academic journal, Fink’s research suggests that the fibers carrying electrical signals could be woven into the wearable smart fabric for “applications in physiological monitoring, human-computer interfaces, and on-body machine-learning.” Incorporating those capabilities into smart fabric required first embedding hundreds of silicon digital chips into casting pre-forms before spinning that into a piece of wearable fabric.

Each string of flexible fiber reaches tens of meters in length, containing hundreds of intertwined, digital sensors that monitor temperature changes and store memory. Each digital fiber, for instance, can collect and store information on changing body temperatures, garnering real-time inference for the wearer’s activity throughout the day. In addition to tracking and collecting data on physiological measures, the smart fabric retains the information gathered and “harbors the neural pathways” necessary to understand that data and infer the future activity of the wearer.

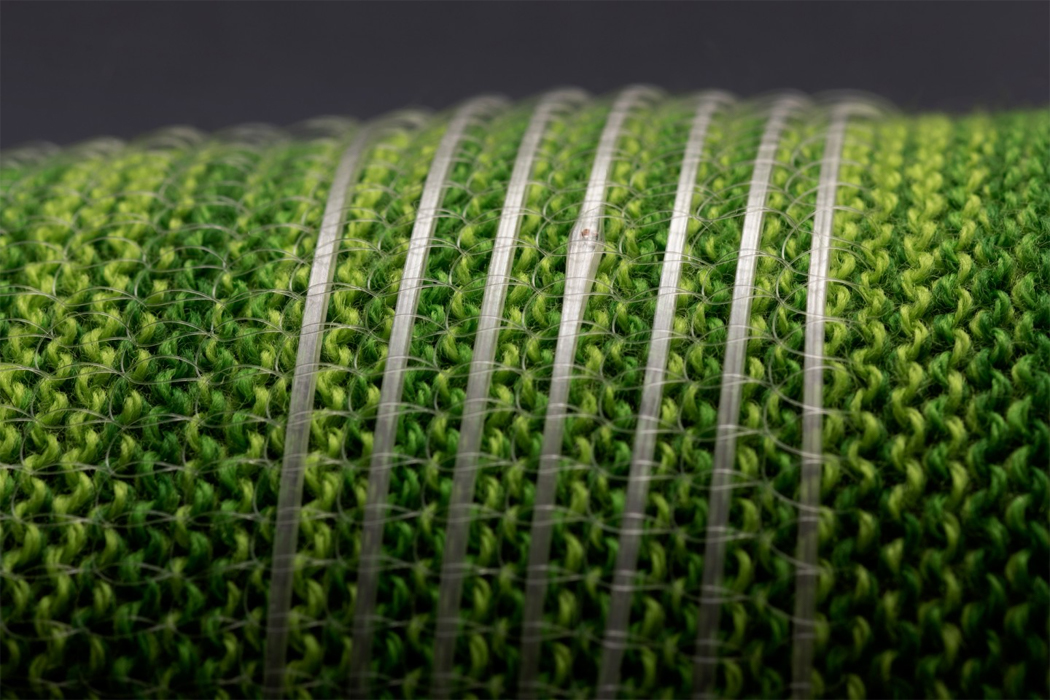

Thin enough to slide through the eye of a needle, the smart fabric is woven with hundreds of laced digital chips that still remain undetectable to the wearer. Forming a continuous electrical connection, the textile fiber also weaves a neural network made up of 1,650 AI connections into the smart fabric, pushing the new development even further. Capable of collecting 270 minutes worth of changing body temperatures and storing a 767-kilobit full-color short film as well as a 0.48-megabyte music file, the smart fabric can retain all of this and store it for two months at a time without power.

Designer: Yoel Fink

Each string of fabric is intertwined with fibers that contain hundreds of digital chips to monitor body temperature and track memory devices.

When woven together, the fibers form a string of fabric thin enough to pass through the eye of a needle.

The fabric is thin enough that Gabriel Loke, a Ph.D. student at MIT says, “When you put it into a shirt, you can’t feel it at all. You wouldn’t know it was there.”

0 Commentaires